Britain Pit

Britain Pit, owned by the Butterley Company, was sunk in 1827 to 125yds deep and is thought to be named after Gabrial Britain who owned several mines in the Newlands, Golden Valley area in the early 1800s.

In 1848 it was extended to 250yds deep and mined the Deep Soft Coal seam at 160 yards deep, the Deep Hard Coal seam at 185 yards deep and the Low Main seam at 241 yards deep.

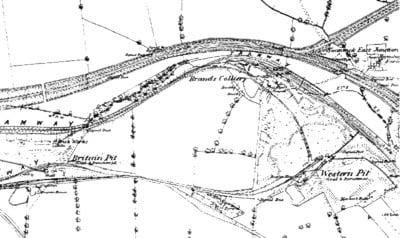

Fig.1 This map from 1881 shows the location of Britain Pit together with Brands Pit and Western Pit, which were later operated as part of Britain pit as ventilation, pumping and upcast shafts.

This area is now occupied by the Swanwick museum site, Midland Railway Centre.

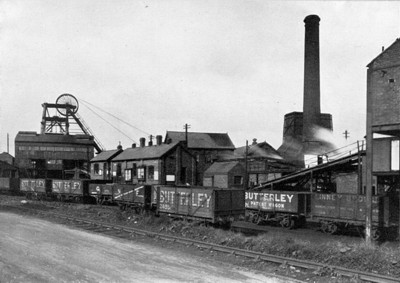

Fig.2 This picture from a Butterley Company publication, shows Britain pit in the 1930s

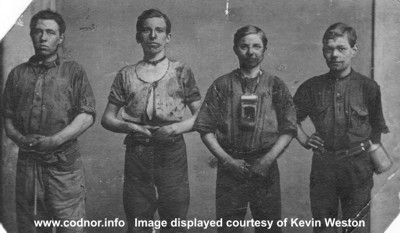

Fig.3 Four young Britain Pit Miners circa 1916. The young lad with the lamp hanging around his neck is Alwyne Ryde. Born in Ripley in 1901 and started work at Britain pit when he was about 13 years old. He went on to work at collieries in Spondon, Ripley and Denby Hall.

He lived most of his life in Codnor until his death in 1986.

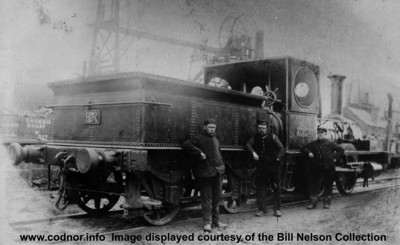

Fig.4 Butterley 0-4-0 shunter Adeline; Information on back of picture documents location as Britain Pit circa 1890. Image displayed courtesy of the Bill Nelson collection and made available by Jacksdale & Westwood Community & Heritage group.

A Mines inspectors Report for 1908 shows Britain Pit was managed by Mr H.O. Bishop and the Under manager was Mr J Henshaw. The pit employed 286 people below ground and 68 above.

Britain pit closed in 1946

In 1874 unrest in the mining industry led to widespread strikes throughout the country. At a meeting at Codnor on the 13th April 1874, the Butterley Company miners unanimously voted to support the strike by ceasing work until Sir John G Alleyne of the Butterley company agreed to meet with them and discuss their grievances, which were as follows.

1. The company had taken off a premium of 2d. per ton without consulting the conciliation board (setup in 1873 by the company to settle disputes).

2. At Britain Colliery, a new, wider screen had been introduced which "robbed" the men of at least 1 cwt. per ton of coal raised.

3. Payment for heading and gate ripping had taken off the amount of 4s 6d per yard and upwards.

4. The payment of 1s 3d per ton for slack had also been taken off.

5. The company had started to fill Cannock Chase trucks with the intention of defeating the miners' strike in that district.

Sir John G Alleyne refused to meet with the representatives of the striking miners and eventually the men returned to work on 7th May 1874. However the Butterley Company prevented eleven of the striking miners from returning after they were accused of taking a prominent part in the dispute.

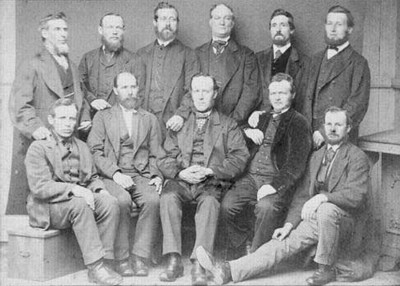

Fig.5 This postcard of the eleven miners "Victimised by the Butterley Company" was produced as part of a campaign to have them reinstated. Although the men were never charged of any crime, they were refused further employment at the Butterley company.

Their names are as follows.

Back Row left to right: Samuel Shooter, G Brown, S Cox, G Taylor, T Vickers, J Statham

Front row left to right: J Seal, William Purdy, T Wheeldon, J Wright, Thomas Purdy

The following details of Britain Colliery are taken from a Butterley Company publication dated 1907.

WINDING ENGINES. Pair of horizontal engines made by the Butterley Company: diameter of cylinders, 30", length of stroke, 56 ½ ".

UNDERGROUND HAULAGE. This is on endless rope underneath tubs principle, on all the main roads, two small electric main rope haulages being used on steep gradients inbye. Two haulage motors, 75 h.p. and 50 h.p. working “C” pulley friction gears, which are further divided up inbye by further friction clutches. Voltage 230. direct current.

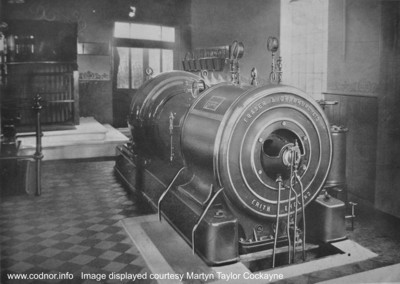

POWER HOUSE. Pair of direct current machines. 60 K.W. capacity. each driven by double belts; single cylinder slide valve engines.

One 200 K.W. Exhaust Type Turbo and Generator. with condenser,‘receiver. cooling pond, etc.

Fig.6 Britain Pit Power House 1907, showing the Fraser & Chalmers Rateau Turbine.

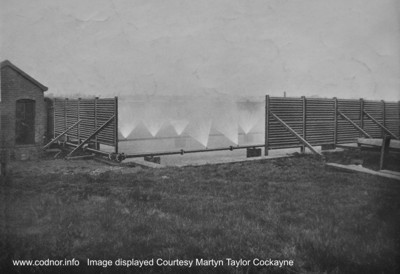

At present the whole of the electricity generated during the day is by the Rateau Plant from the exhaust steam from the Winding Engines, the other direct current machines being kept as spares. Only five boilers are now in use, whereas. before the Rateau Plant was started, six were in use, and a larger amount of electric power is now available, a 50 h.p. underground endless rope haulage motor being added, and electric motor for chopping horse feed. and two 10 h.p. auxiliary haulage electric motors. The Electric Plant at these collieries has been put down by the Morley Electric Company, Ernest Scott & Mountain, M. B. Wild &Co., Birmingham, P. J. Mitchell, London, and Brush Electric Co., Loughboro‘.Fig.7 Britain Pit, Rateau Plant Cooling Pond 1907

VENTILATION. The workings are ventilated by a Waddle Fan, diameter, 30'. Engine; diameter of cylinder, 26" stroke, 30".

PUMPING. An old beam type of pumping engine is situated at Butterley Park, about half a mile south-east of Britain Colliery. This pump deals with a large quantity of water from south old workings, and another pump, situated at Brands. deals with the water on the north side. lt is proposed to concentrate these pumping stations, and a scheme has been prepared for same, and is being gradually carried out.

Information for this page was obtained from the following sources.

The Heritage of Codnor & Loscoe, by Fred S Thorpe 1990

The Coal Authority.200 Lichfield Lane,Mansfield,Nottinghamshire,NG18 4RG.

Durham Mining Museum website: http://www.dmm-gallery.org.uk

History of Nottinghamshire Miners Volume 1" by Alan R Griffin